How the PROVITAB 3™ System Works

PROVITAB 3™ is engineered for seamless, automated chlorination, providing consistent and reliable water treatment with minimal operator intervention.

about the product

Automated Chlorination, Innovated

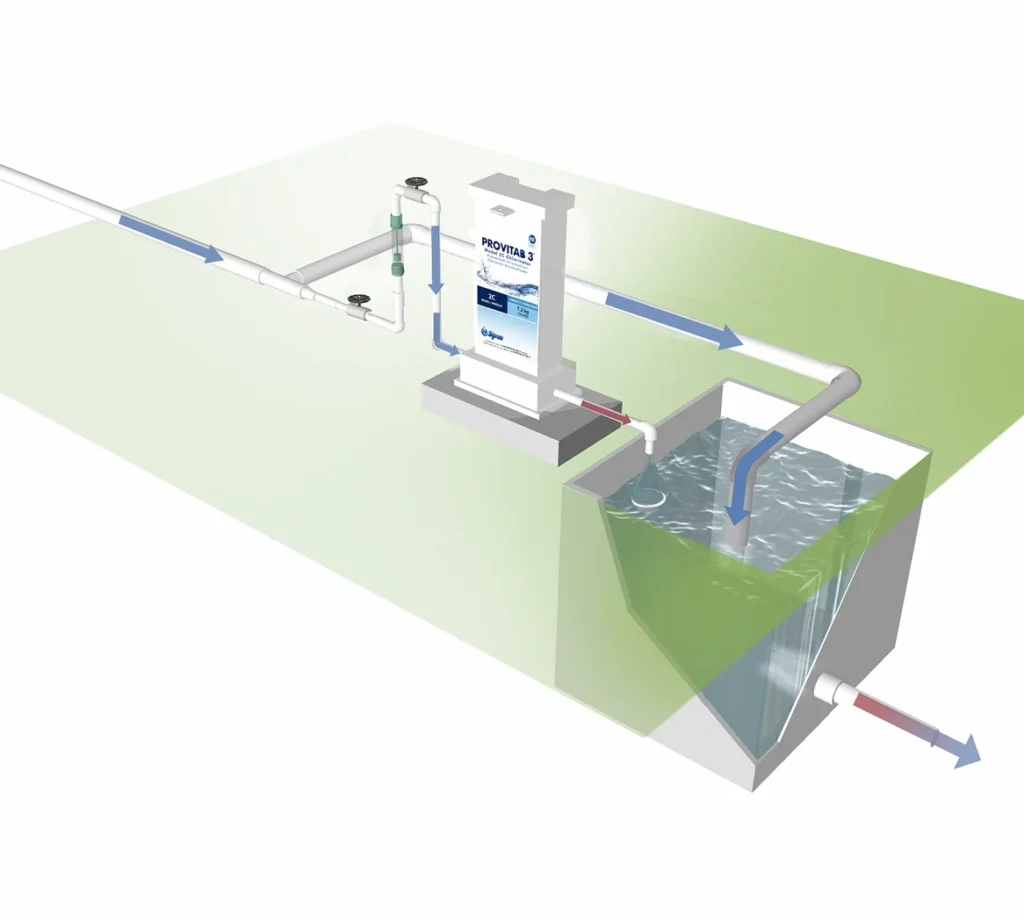

PROVITAB 3™ utilizes a dry chamber chlorination process, offering both Gravity and Injection models to cater to specific operational needs.

Water interacts with organic, stabilized PROVICHLOR™ tablets within the chamber, dissolving them at a controlled rate to release chlorine. This ensures precise and uniform chlorination, eliminating the guesswork and inconsistencies associated with traditional methods.

EPA Approved Uses for PROVITAB 3™

Cooling

towers

recirculating

water - Cooling Towers

air

washers

Evaporative

condensers

livestock drinking water disinfection

animal housing facilities disinfection

Green houses

& food crop

nonporous contact surface & equipment Sanitization

egg processing

plants

Swimming pool

water disinfection

drinking

water

sewage &

wastewater

Emergency

disinfection

Key Differentiators of the PROVITAB 3™ System

65%

Available Chlorine

more stable than

non-stabilized chlorine

Key Differentiators of the PROVITAB™ 3 System

65%

Available Chlorine

more stable than

non-stabilized chlorine

System Configurations

Adapting to Your Water Treatment Needs

PROVITAB 3™ is designed with versatility in mind, offering two operational modes to suit a wide range of water treatment applications. Whether your setup requires simple, electricity-free operation or pressurized, high-precision delivery, PROVITAB 3™ offers a solution.

Configuration

The Gravity System

The gravity-fed PROVITAB 3™ system operates without electricity, making it well-suited for a range of applications. Water enters the chamber, dissolves the PROVICHLOR™ tablets, and flows into a mixing tank by gravity, helping maintain effective chlorination.

- Controlled Water Input & Tablet Dissolution

- Natural Water Flow Through the Chamber

- Consistent Distribution via Mixing Tank

- Simple Design for Minimal Maintenance

Configuration

The Injection System

The injection-fed PROVITAB 3™ system utilizes a robust pump to introduce chlorinated water directly into the main water line. This configuration is particularly suitable for facilities with pressurized systems, such as industrial settings or large-scale water operations

- Pressurized Chlorinated Water Delivery

- Maintains Consistent Outlet Pressure

- Enhanced Mixing Through Circulation

- Reliable Control for High-Pressure Systems

Process

Flexible Installation & Configuration

01.

Consultation

Our experts assess your specific application to determine the optimal PROVITAB 3™ system type and size.

02.

Installation

Our technicians handle the installation, helping achieve proper integration with your existing water treatment system.

03.

Consultation

We provide training on system operation and maintenance, helping you become familiar with the system’s functionality.

04.

Support

Our team offers ongoing support to help maintain a reliable system performance.

Why PROVITAB 3?

System Benefits

Improved Water Quality

PROVITAB 3™ is designed to support steady treatment, helping improve water quality for its intended applications.

Less Turbidity

PROVICHLOR™ has minimal impact on water pH and does not contribute to water hardness, helping maintain clear, consistent water quality.

Chlorine Availability

PROVICHLOR™ tablets offer 65% available chlorine. Containing stabilized chlorine, they prolong chlorine availability and support long-lasting disinfection.

Operator Safety

The cartridge system reduces direct contact with chlorine to support safer handling by operators.

How We’ve Helped Our Valued Clients

“Residual chlorine was detected in downstream tanks, a result not achieved with calcium hypochlorite.”

Gerald Mgina

“Enhanced safety due to reduced operator contact with the product. No equipment wear, resulting in reduced maintenance requirements.”

Cheyo Kanuda

01

What maintenance is required for the PROVITAB 3™ system?

- Regularly inspect the system for leaks or damage and replace cartridges as needed.

- Clean the mixing tank and check the flow control valve or pump regularly.

- Perform routine performance calibration checks to support accurate chlorine dosing.

Note: This guidance outlines common maintenance tasks and is not exhaustive. Always refer to the manufacturer’s instructions and comply with applicable regulatory requirements.

02

How are PROVICHLOR™ cartridges replaced?

To replace a cartridge, use the provided plastic handle to safely remove the empty unit and insert a new one. After replacement, check and adjust the flow control valve as needed to maintain the desired water flow rate.

Note: Always wear appropriate personal protective equipment (PPE) and follow standard chemical handling procedures.

03

What are the optimal settings for the flow control valve in the Gravity system?

The optimal setting depends on your specific application and water flow requirements.

Monitor the free chlorine residual in the chlorinated water from the mixing tank, and adjust the valve accordingly to maintain the desired residual level.

Read the Directions for Use on the product label to determine the appropriate chlorine level for your application.

04

How are pressure issues in the Injection system troubleshot?

- Check that the pump is operating correctly and that all connections are secure.

- Verify that the pressure gauge provides accurate readings, and adjust the pump settings if necessary.

If the issue persists, please contact our support team for further guidance.